Robots Programming

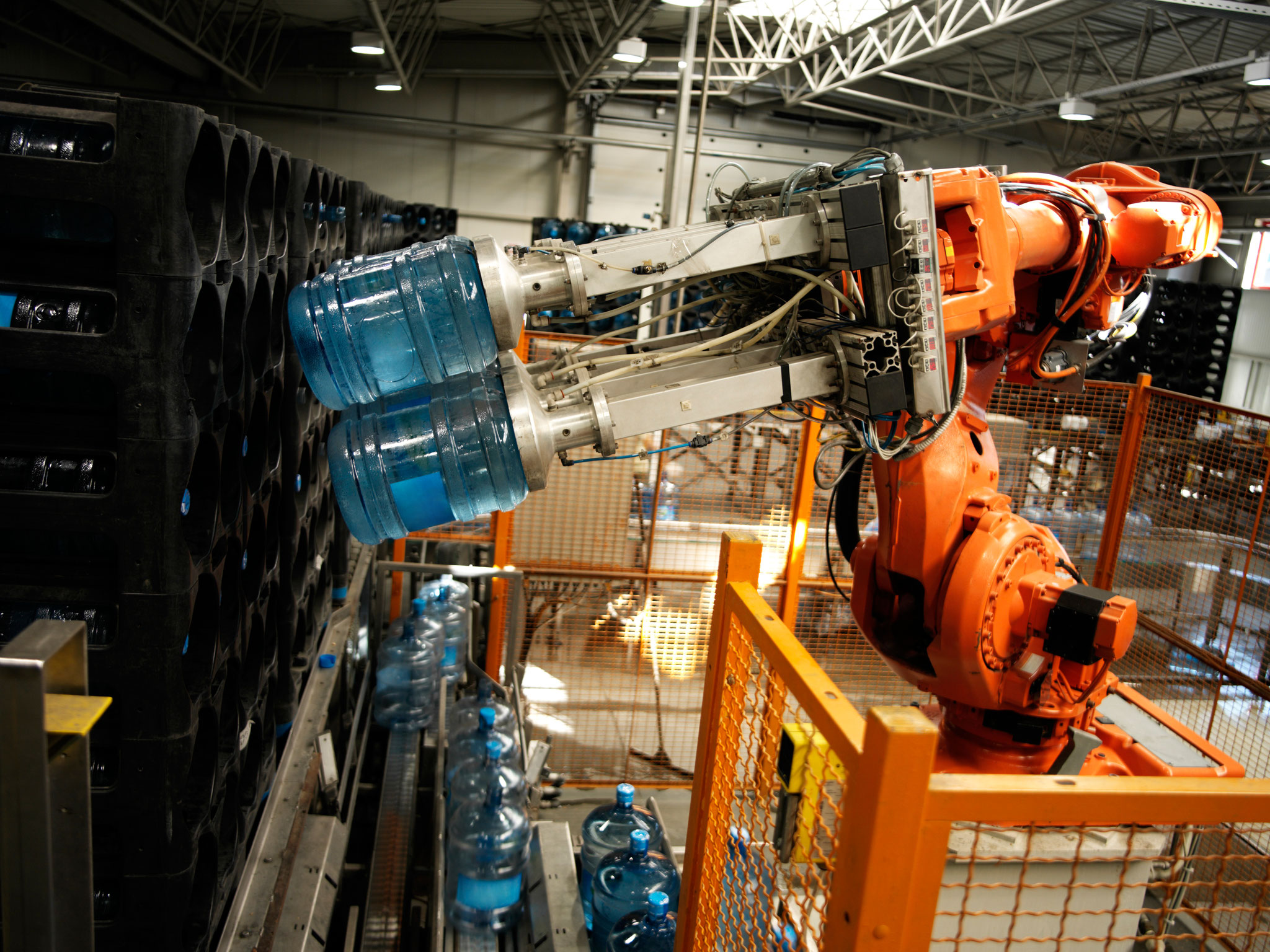

Due to the constant increase in the degree of automation, even of simplest applications, the programming and commissioning of industrial robots are increasingly becoming the focus of today's manufacturing industry. A high level of technical understanding and good spatial imagination are the basic requirements. The software plays a decisive role in the performance of a system. The better the programming is adapted to all individual conditions on site, the greater the benefit that a robot delivers. With around 20 years of experience in dealing with industrial robots, our team has a broad and deep know-how to find the best solution for your tasks. For our customers we offer a wide range of services not only from a single source but for the most diverse robot systems, too.

Kuka

- Sunrise.OS

- KRC 4

- VKRC 4

- KRC 2

- VKRC 2

- SafeOperation

ABB

- IRC5

- S4

- SafeMove

Fanuc

- R30-iB

- R30-iA

- R-J3

- DCS

Online Programming and Commissioning

The programming and commisioning is always online, that means at your location. We program for you the manufacturers Kuka, ABB or Fanuc.

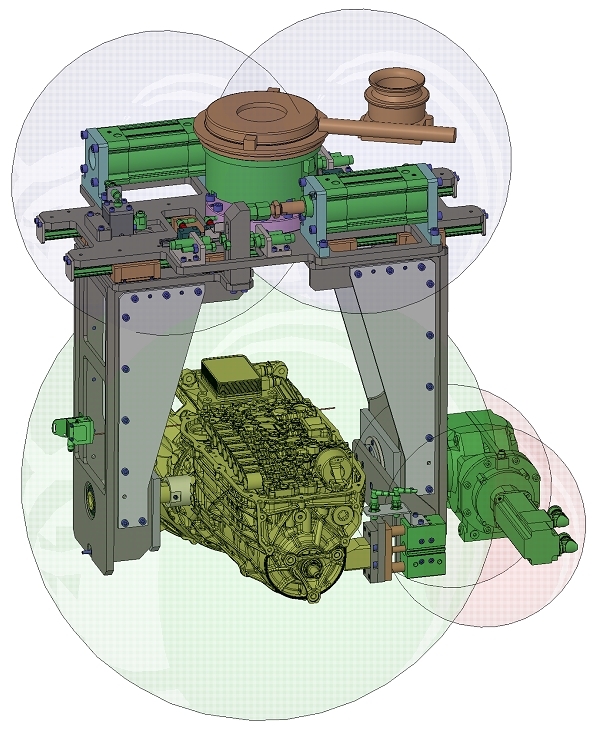

Depending on the requirements, we also configure the bus system, additional axes, linear units, tools or other subsystems.

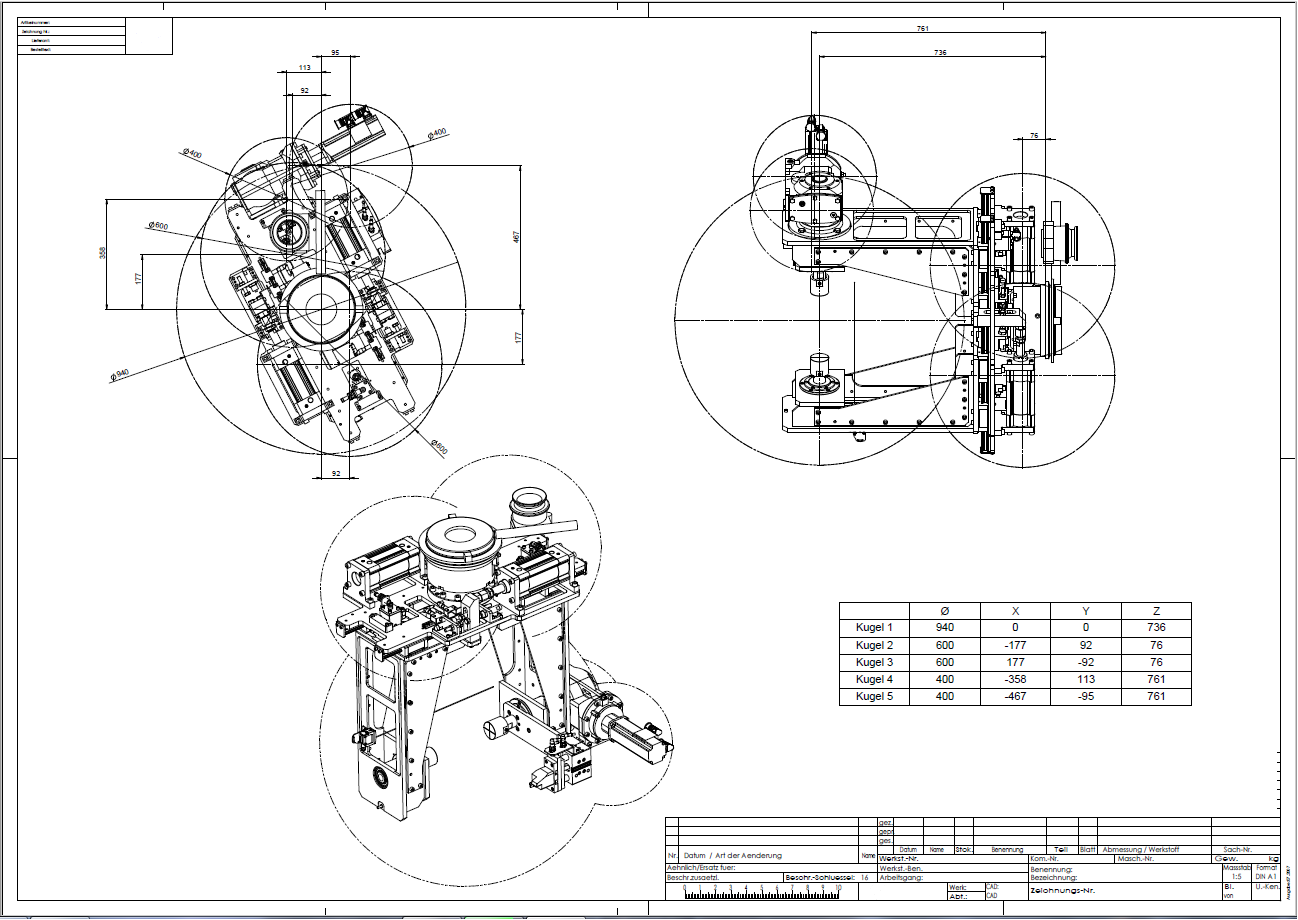

SafeOperation, SafeMove and Dual-Check-Safety

Our employees are certified safety engineers, enabling creation, configuration and validation of the safety configuration according to current safety regulations. For this we either request the necessary drawings from the design department of our customers, or we create the necessary security rooms ourselves, if the customer provides us with the CAD files.